Operational Excellence Study for 8554189359, 693126012, 657170919, 269574800, 570069108, 4692132018

The Operational Excellence Study for identifiers 8554189359, 693126012, 657170919, 269574800, 570069108, and 4692132018 reveals critical insights into effective process optimization. By examining specific case studies, the analysis uncovers tailored methodologies that enhance operational efficiency. Furthermore, the study highlights best practices that can sustain competitive advantages. Understanding these strategic frameworks raises essential questions about their application in diverse organizational contexts and the potential for broader impact.

Overview of Operational Excellence Frameworks

While organizations strive for continuous improvement, understanding the various frameworks of operational excellence is crucial for achieving sustainable performance.

Lean methodologies focus on waste reduction and efficiency, fostering a culture of continuous refinement.

Conversely, Six Sigma emphasizes data-driven decision-making to minimize variability and enhance quality.

Together, these frameworks provide strategic tools that empower organizations to achieve operational freedom and superior results in competitive environments.

Case Studies Analysis of Identifiers

The analysis of case studies in operational excellence reveals critical identifiers that contribute to successful implementation of various frameworks.

Through identifier analysis, patterns emerge, illustrating how specific strategies enhance performance and drive results.

These case studies highlight the significance of tailored approaches in diverse environments, empowering organizations to adopt innovative practices that foster autonomy and encourage continuous improvement in operational efficiency.

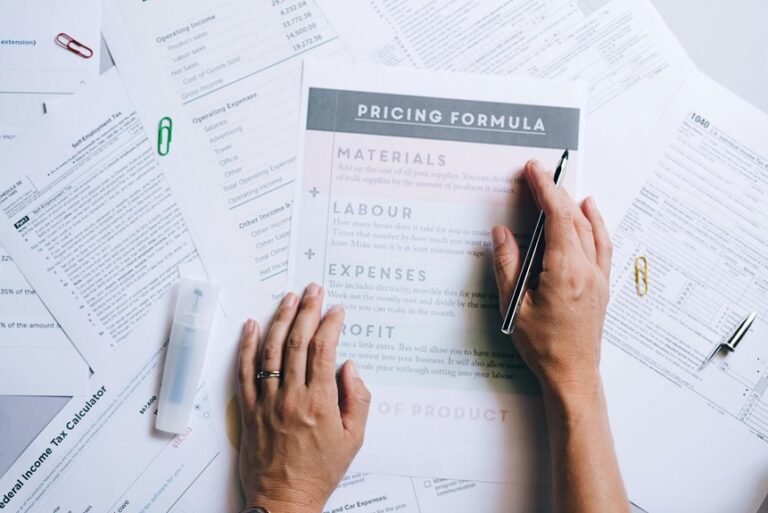

Best Practices for Process Optimization

Achieving process optimization requires a strategic approach that integrates best practices tailored to an organization’s specific needs.

Implementing Lean methodologies fosters a culture of continuous improvement, focusing on optimizing the value stream while systematically identifying and eliminating waste.

This alignment not only enhances operational efficiency but also empowers teams, promoting a liberated work environment that encourages innovation and sustainable growth.

Strategies for Sustaining Operational Efficiency

How can organizations ensure that operational efficiency is not only achieved but also sustained over time?

By adopting lean methodologies and fostering a culture of continuous improvement, businesses can streamline processes and eliminate waste.

Regular assessments, employee training, and feedback mechanisms are essential strategies that promote adaptability and innovation, ensuring that operational efficiency remains a priority in an ever-evolving marketplace.

Conclusion

In conclusion, the Operational Excellence Study for identifiers 8554189359, 693126012, 657170919, 269574800, 570069108, and 4692132018 illuminates a transformative path toward unparalleled operational supremacy. The meticulous analysis of these cases reveals not merely best practices, but a veritable blueprint for transcendence in process optimization. By championing data-driven decision-making within a culture of relentless innovation, organizations are not just improving; they are catapulting themselves into an echelon of efficiency that redefines industry standards.